Advantages of Deep Learning for Industrial Automation

Advantages of Deep Learning for Industrial Automation

Welcome to this series of blogs on Deep Learning for Machine Vision. In this first blog we will be exploring the benefits of using Deep Learning in tandem with vision systems to automate industrial processes.

Let’s start by identifying some key terms.

Deep Learning vs. Machine Learning

This is a key question in machine vision: what is the difference between machine learning and deep learning?

As the next step in artificial intelligence (AI), machine learning is defined by systems that can function and process with less human interaction than standard computers. Deep learning is then in turn an evolution of machine learning, which refers to systems that utilise neural networks modelled on the human brain to make inferences.

Thinking about industrial automation, machine learning reduces the need for human intervention, whereas deep learning goes further, with the emphasis on trying to remove human intervention altogether. Of course, there will probably always be some level of human intervention, but this point underlines one of the central differences between the two terms.

Industry 4.0: deep learning is a pillar of the current age of industrial growth, allowing menial imaging to be automated – thus saving time and money.

The main trade-off between machine learning and deep learning is that machine learning will require less computing power but more human interaction, and on the other hand deep learning will require more computing power but less human interaction.

Deep Learning in Machine Vision Systems

When paired with machine vision systems, deep learning can produce some rather spectacular results. Using high quality cameras and lenses and powerful embedded systems, combined with industry-leading machine vision software Matrox Imaging Library (MIL) and Matrox Design Assistant (DA), you’ll have a powerful and dynamic deep learning machine vision system in your hands.

In the context of industrial automation solutions, a deep learning machine vision system can dramatically increase speed in factories, production lines and quality control (QC) processes by removing unavoidable margins of human error and freeing up human time to problem-solve in other areas.

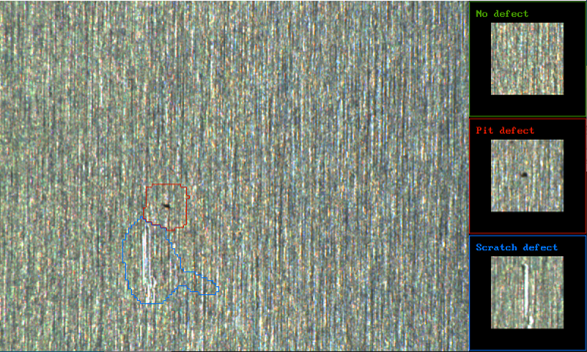

Combining deep learning with the latest machine vision technology can lead to extremely effective defect detection in industrial settings.

This shifts the workload of data scientists and engineers from ongoing analysis (as with traditional machine vision and, to a degree, machine learning) towards preparation in the form of calibration and data set acquisition to train the convolutional neural network (CNN).

Deep Learning Data Sets for Machine Vision

In the context of deep learning, a data set is the data we use to train a model. Before you can get going with your deep learning application, there is a lot of rigorous preparation that needs to be done, and it all starts with your data set.

This refers to a collection of samples of the data containing the features required for your application. These samples will be used for training and validation and they should contain as many representations (good and bad) of the object as possible.

In any deep learning machine vision project, the purpose of this data is to train the convolutional neural network to make inferences that align with the purpose of your mission intentions, then test and validate these decisions using further data from the set.

How Much Data is Required for a Deep Learning Data Set?

The amount of data you choose to gather is ultimately dependent on the complexity of the object you are imaging, and how many possible variables there will be.

For example, if you are designing a system to detect paint colours on automobiles in a factory, you will need to consider variables for colour, finish, lighting, etc.

However, if the application is even more complex than that, for example, a deep learning vision system for an autonomous automotive project, there are many more factors to consider.

Data sets used for deep learning in road traffic environments must be as rigorous as possible.

A self-driving car will need to objectively classify and respond to both objective and subjective signs and hazards in real time, so the data set may well number in the tens of thousands.

It will be up to you as the data scientist to decide how much data to include in your data set, but the key line is that the more data you present to the model, the less likely it will be to make mistakes further down the line – and in the shoes of an OEM or system integrator, this could be the difference between making and breaking your deep learning machine vision project.

Deep Learning Machine Vision Applications

Industries that can benefit from applying deep learning to their industrial automation vision systems are those that play to the core advantages of deep learning: classification, recognition, reading, and detecting.

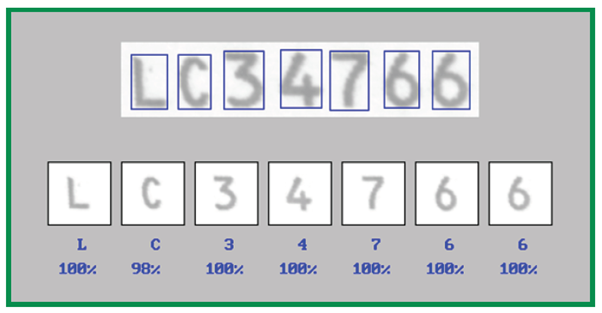

Deep learning excels at industrial optical character recognition (OCR).

Matrox SureDotOCR is perfect for reading CIJ printed characters

As with the data sets, the more basic the object you are imaging, the easier deep learning is to implement. Sorting fruit, for example, works very well – blemishes are easy to recognise and so automating the passing or rejection process can save lots of time.

Sorting apples using deep learning.

Industries that rely on automation itself as the USP, for example autonomous vehicles, can also widely benefit from deep learning.

Cutting Edge Deep Learning Solutions from ClearView Imaging

Stay tuned to this series of blogs as we continue to explore deep learning in a variety of machine vision contexts.

Whether you’re an OEM, a system integrator, engineer or even an end user, be sure to check our great range of machine vision products for the best machine vision components on the market.