7 Main Challenges of Label Verification

7 Main Challenges of Label Verification

Welcome back to our series of blogs on Label Verification.

This time we will be looking at the major challenges you may face during the label verification process and discussing the best tactics to deal with these issues.

Label verification systems are key to stepping up industrial automation in factory settings, and the following blog post will dive into seven common challenges you may face when implementing a machine vision label verification system.

Whether you’re looking to invest in a developed system or looking to build your own label verification solution with Matrox Imaging Library, this blog post should prove useful to you.

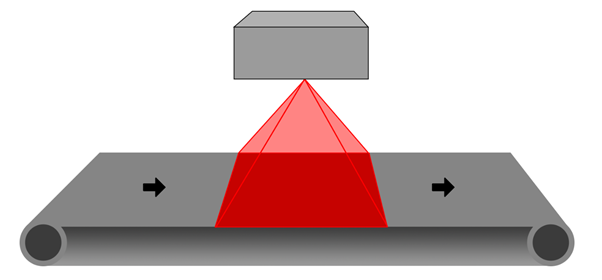

Challenge 1: Area Scan vs. Line Scan

Area scan cameras lie at the heart of most traditional machine vision systems. They provide a fixed resolution (i.e. 1920 x 1080), and are good at capturing scenes and settings.

Line scan cameras on the other hand only have a fixed horizontal resolution (i.e. 4096). Due to this, their versatility is limited, but in certain applications they have a big edge over area scan cameras.

If pack sizes vary, as long as the line scan camera has sufficient horizontal resolution, the vision system will be accurate and future proof.

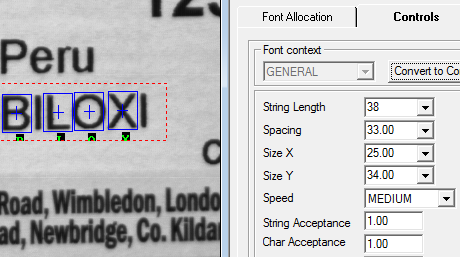

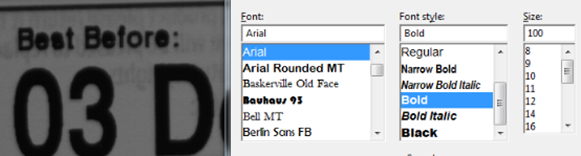

Challenge 2: Creating Fonts

The success of a label verification vision system largely hinges on the system’s ability to recognise characters in a font family. Many systems will need a custom font to be created, whilst others may support existing font types.

Custom Font Creation

For example, our checkmate range supports TrueType fonts, as well as the ability to create custom fonts based on pre-existing labels. How? With Matrox String Reader.

Within Matrox Imaging Library is Matrox’s own patented, powerful, and highly practical character recognition software, comprising SureDot OCR, String Reader and OCR.

The String Reader tool is based on a sophisticated technique that uses geometric features to quickly locate and read text made up of solid characters in images where these characters are well separated from the background and from one another.

The tool handles text strings with a known or unknown number of evenly or proportionally spaced characters. It accommodates changes in character angle with respect to the string, aspect ratio, scale, and skew, as well as contrast reversal.

TrueType Font Support

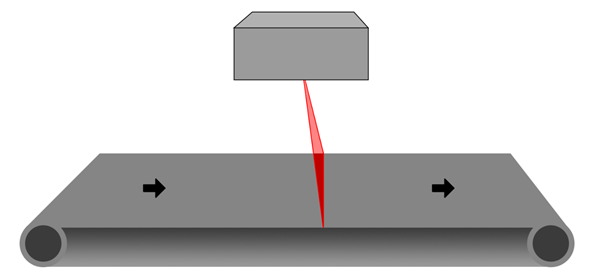

Challenge 3: Modifying Fonts

Some vision systems only support custom font creation. In these instances, whenever a new font is needed, or there is an issue with a font, it can be complicated to modify them.

Custom Font Modification

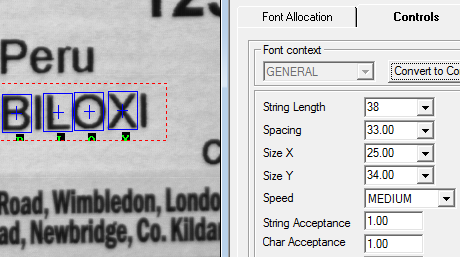

Thanks to String Reader, our CheckMate range of label verification systems will allow you to go in and modify specific characteristics of the font you are working with, such as spacing, character height, and string length. Changing fonts can also be easily done with these systems, allowing you the flexibility to tackle whatever may come your way.

Challenge 4: Creating Jobs

An essential part of any good label verification vision system is the ability to create jobs and workflows. You need to be able to tell a vision system what items on the label or SKU need to be inspected or not.

Ideally you also need to be able to customise what items on the label you want the label verification system to check. You want the system to be able to perform a series of tasks on each label, and have the ability to determine these with ease as a user.

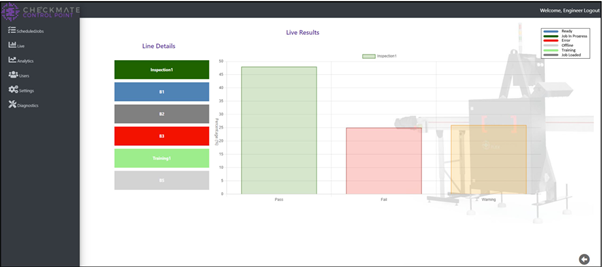

CheckMate has a Wizard flow tool, which not only ensures creating jobs is straightforward and easy to do – it also features inbuilt failsafe measures that prevent the system from operating until all jobs and outlined processes work. This means you won’t get caught out months into your project – you’ll only be able to get going once effective results are obtainable.

You can choose from a fully customisable list of items present on the label in CheckMate

With the ability to set regions of interest, such as 1D barcodes, 2D QR codes, dates, prices, weights, area of origin etc, the problem of assigning specific areas of the label to individual tasks in the Wizard flow has never been easier.

For example, the discount sticker on this strawberry pack can be highlighted and assigned as a ‘flash label’ using CheckMate Control Point. Once programmed, the system then knows how to recognise this sticker in the production line process, including a necessary step in the label verification process.

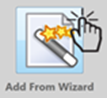

Label results are clear and easily accessible in CheckMate Control Point.

Challenge 5: Modifying Jobs

For a vision system to be reliable, editing existing jobs needs to be straightforward and repeatable.

Even if you need to customise the items that are presented, you ideally want to be able to do this without the need for external custom development.

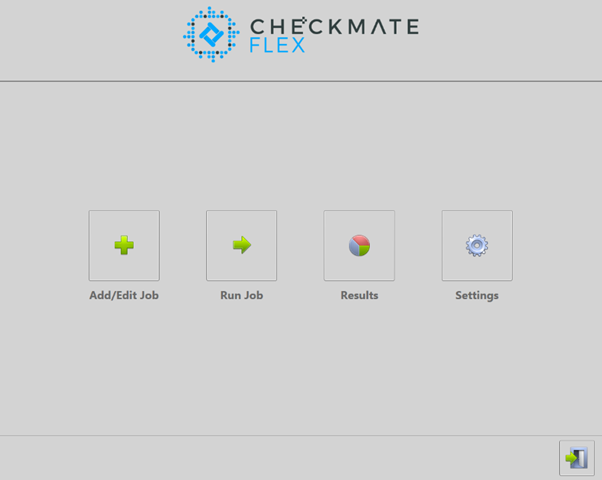

Adding and editing jobs is easy and user-friendly in CheckMate’s UI.

Challenge 6: Product Pack Rotation

What happens when a product pack on the production line passes through upside down, or at a typically illegible angle? Will your label verification system be able to recognise the rotation and adjust for it?

The answer lies in the software. A label verification system will be as robust as the amount of training and programming put into it. It’s a good idea to choose a system from a company that have engineers to assist with the software development, so you can work together to decide how robust to make it – this way you will have a system that can carry out all the tasks you need it to, all the while keeping costs down by not having to enlist external developers.

In our CheckMate systems, we use Matrox’s Geometric Model Finder and Pattern Matching tools to tackle the challenge of pack rotation.

By setting a unique ID as an anchor that the label verification system knows to look for, it will then correct the rotation of the image based on the orientation of the set anchor. For example this unique ID could be a set image or flash label.

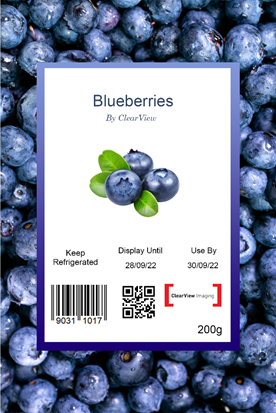

A good anchor point on this label could be the image of blueberries, or the ClearView logo, as these unique IDs will always look the same from the correct angle.

Challenge 7: The CIJ OCR Challenge

‘CIJ’ or Continuous Inkjet is a non-contact method of industrial printing that produces a continuous flow of ink droplets from a printhead nozzle. These are applied to the surface of a package or label. Using electrostatic deflection, as many as 120,000 droplets can be printed per second.

While this is an extraordinarily efficient method of printing on large quantities, problems such as incorrect line speed, dirty printheads, and non-optimal distances between printhead and printing surface can lead to issues in legibility with CIJ printing. This creates potential issues for label verification, as some printed characters may be legible to human eyes but challenging for vision systems. Conversely, it’s also possible that a vision system will read something that human eyes wouldn’t.

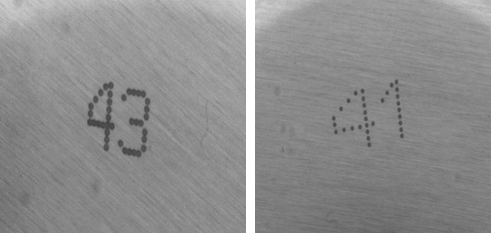

A good label verification system will need to recognise the ‘4’ in both instances, despite their differences.

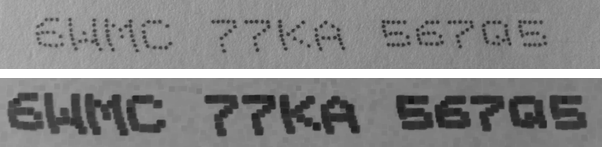

OCR has typically in the past only thrived in settings with single-stroke characters, such as in automatic number plate recognition (ANPR). Rudimentary machine vision algorithms struggled to interpret the internal boundaries of characters with broken lines, and as CIJ consists of individual dots, pre-processing steps had to be taken to convert these characters from dots to single-stroke in order for vision systems to read these them. This is known as morphology.

A visualisation of morphology

Check out our demo of Matrox SureDotOCR with the Triton from LUCID Vision Labs

Vision Solutions from ClearView Imaging

We understand that implementing a label verification system is a careful operation with many factors to consider. At ClearView Imaging, not only do we provide the solutions you will need for your production line, but we also have a great team of technical engineers and vision experts with the knowledge and experience to help you with label verification procedure. Whatever the question or query, feel free to get in touch via our contact page.

Stay tuned to our blog posts as we continue to explore machine vision's many theories and practical applications in a variety of settings and contexts!

Whether you’re an OEM, a system integrator, engineer or even an end user, be sure to check our great range of machine vision products for the best machine vision components on the market.