SureDot OCR Tool for Optical Character Recognition in Machine Vision

SureDot OCR Tool for Optical Character Recognition in Machine Vision

Welcome back to Clearview blog! Here you’ll find regular articles about the latest in machine vision, including the latest breakthroughs in cutting-edge technology, technical theories, and insightful discussions on all things related to machine vision.

This is our third blog in a series on Optical Character Recognition (OCR) for Machine Vision. So far in this series, we have introduced Optical Character Recognition (OCR) and explored its history and uses, and taken a look at the String Reader tool from Matrox Imaging.

In this blog post, we’ll introduce and explore the SureDot OCR Tool from Matrox Imaging, and explore the unique advantages that can be gained with it. First, let’s look at CIJ printed text.

CIJ Printing

CIJ, or Continuous Inkjet, is a non-contact method of industrial printing that produces a continuous flow of ink droplets from a printhead nozzle.

These droplets are fired at the surface of package and labels in sequence to print text. Using electrostatic deflection, as many as 120,000 droplets can be printed per second.

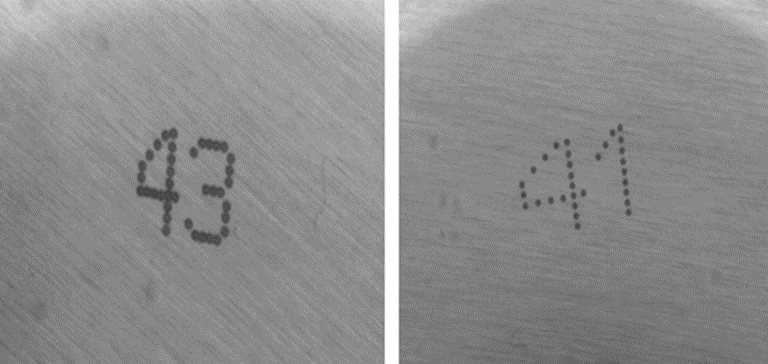

While this is an extraordinarily efficient method of printing on large quantities, problems such as incorrect line speed, dirty printheads, and non-optimal distances between printhead and printing surface can lead to issues in legibility with CIJ printing. This creates potential issues for label verification, as some printed characters may be legible to human eyes but challenging for vision systems. Vice versa, it’s also possible that a vision system will read something that human eyes wouldn’t.

A good OCR/V system will need to recognise the ‘4’ in both instances, despite their differences.

The Traditional Machine Vision Approach to Reading CIJ

Historically, there have been two main challenges standing between machine vison systems and successful OCR for CIJ text.

1. Converting ‘dot’ characters into single-stroke characters

OCR has typically in the past only thrived in settings with single-stroke characters, such as in automatic number plate recognition (ANPR).

Dot characters and single-stroke characters

Rudimentary machine vision algorithms struggled to interpret the internal boundaries of characters with broken lines, and as CIJ consists of individual dots, pre-processing steps had to be taken to convert these characters from dots to single-stroke in order for vision systems to read these them. This is known as morphology.

Morphology of Alphanumerical Characters

The process of morphology involves dilating each of the dots by a radial pixel value. In the below example, we can see how this process involved some trial and error.

Furthermore, in the next example we can see how attempts to universally expand every dot by the same amount wasn’t always successful – some areas still contain gaps (which break the linearity), whilst other areas can become overcrowded and too swollen to read.

2. Dealing with transformed text

Just a few examples of variations in CIJ printing

Considering just how many different ways that alphanumerical characters can vary in appearance from factors such as printing errors, imperfect lighting, unsuitable illumination and bad camera positioning, this was an extremely long and painstaking process to get to the point of actually having an accurate, repeatable, reliable CIJ OCR machine vision system. This approach is now regarded as too time-consuming to keep up with modern industrial environments.

These difficulties led Matrox Imaging to take an overhauled approach to reading dot matrix text with the introduction of the SureDot OCR tool.

SureDot OCR

The SureDotOCR tool is specifically designed to address the challenge of reading dot-matrix text generated by inkjet printers and dot peen markers. It’s easy to use, as you only need to specify the dot size and dimension of the text region, without needing specifying the location.

The SureDotOCR tool is specifically designed to address the challenge of reading dot-matrix text generated by inkjet printers and dot peen markers. It’s easy to use, as you only need to specify the dot size and dimension of the text region, without needing specifying the location.

The tool reads text of variable length, at any angle, with varying contrast, and/or on an uneven background. It can also interpret distorted and overlapping characters, as well as characters of different scales.

SureDot OCR also handles constituent dots that vary in size and are touching each other. It has the capability to recognise punctuation marks and spaces, and supports the creation and modification of character fonts, including pre-defined fonts. The tool also seamlessly handles multiple lines of text, each line capable of utilising a different font. By allowing user-defined constraints, both overall and at specific character positions, the tool enhances recognition rates.

The SureDotOCR tool offers greater robustness and flexibility compared to specialised techniques that convert dot-matrix characters into solid ones for reading with traditional character recognition tools.

How to Use SureDot OCR

SureDot OCR is offered as a tool within Matrox Imaging Library (MIL) X and Design Assistant X machine vision software packages.

MIL X

MIL X is a comprehensive suite of software tools for the development of machine vision, image analysis, and medical imaging applications. It provides a range of tools that cover the entire process, from assessing application feasibility to prototyping, development, and deployment.

MIL X is a comprehensive suite of software tools for the development of machine vision, image analysis, and medical imaging applications. It provides a range of tools that cover the entire process, from assessing application feasibility to prototyping, development, and deployment.

It’s a software development kit (SDK) that offers interactive software and programming functions for image capture, processing, analysis, annotation, display, and archiving. These tools are specifically designed to boost productivity, reducing the time and effort required to bring solutions to market.

Design Assistant X

Matrox Design Assistant X, represents a slightly different option: an intuitive, versatile, and extendable integrated development environment (IDE) for machine vision applications. It empowers users to build vision applications through an intuitive flowchart interface, eliminating the need for conventional programming code. Furthermore, the IDE allows for the creation of a visually appealing web-based operator interface for the application.

Matrox Design Assistant X, represents a slightly different option: an intuitive, versatile, and extendable integrated development environment (IDE) for machine vision applications. It empowers users to build vision applications through an intuitive flowchart interface, eliminating the need for conventional programming code. Furthermore, the IDE allows for the creation of a visually appealing web-based operator interface for the application.

Both solutions are available through Clearview! Check out our Software page for more information.

In the Next Blog…

Next time we’ll be ending our series on OCR as we examine Zebra’s exciting Deep Learning OCR tool. Stay tuned!

Future Focused Vision Systems from Clearview

Want to find out more about revamping a vision system or automating industrial processes? Look no further – get in touch with us. Also, be sure to check out our great range of smart cameras and machine vision software over in our products section!

Here at Clearview, we have a broad range of knowledge and machine vision expertise to help you decide on the right solution for your project.

We offer friendly expertise and a huge range of industry-standard quality machine vision components for printing and packaging, robotics, industrial automation, medicine, life sciences, and the automotive industry, just to name a few.

Our experts are happy to help no matter what your question or problem may be. Feel free to get in touch with us and one of our machine vision experts will be ready to help you get going with your project.