Embedded Vision: What Is It?

Embedded Vision: What is it?

Welcome to the next instalment of machine vision blogs from ClearView Imaging. This week we will be introducing our new topic by answering the question: What is Embedded Vision?

Whether you’re interested in building powerful embedded vision systems, compact embedded vision devices, or are just interested in learning more about the topic, this blog post is for you. Ultimately, embedded vision is the future of many machine vision applications in robotics, industrial automation, medicine, life sciences, and automotive, just to name a few. We hope you enjoy reading.

Edge Computing

In essence, edge computing is where some data or image processing happens on a device itself instead of collecting data using a camera and passing it to a PC to be analysed. An embedded computer/device will sit at the ‘edge’ of a network and interacts with a server/PC for additional processing and analysis, rather than the traditional machine vision method of a camera connected to PC for machine vision processing.

What is Embedded Vision?

So, what is embedded vision? This is actually a harder question to answer than one might initially expect.

To some, embedded vision is a vision system that will save money by having cheaper hardware and components than a traditional machine vision system. To others, the emphasis of embedded vision lies in its compact form, taking up less space than typical machine vision systems.

Speaking generally, embedded vision systems or devices usually:

- Cost less

- Consume less power to run

- Take on a compact form

- House all components internally, taking on an all-in-one design

Let’s devise a checklist of what an embedded vision system usually comprises.

What do you need for an Embedded Vision System?

Embedded Vision Systems will always consist of at least a camera/sensor, typically with a lens, a processor, and running some software. This is where contended definitions come in, as a system with all these parts could have any combination of form, shape, size, and function.

Let’s start by exploring how each of these components can vary, resulting in a range of different embedded vision systems.

Choosing a Camera for Embedded Vision

There are a few constraints when considering which kind of camera to use for an embedded vision system.

If you’re building a larger embedded vision system, camera size tends not to be an issue, and so you can really work with whatever camera suits the system best. In other words, you can freely choose FPS, colour or monochrome, megapixel resolution etc, and the camera will most likely be able to slot nicely into your machine and be locked away in its casing.

If it’s a more compact device you’re creating, perhaps such as a portable handheld smart camera solution, then the camera choice becomes a lot tougher. If the device calls for heavy processing, or a powerful illuminator, then you must think carefully about how much space and component each component will use.

This might mean you opt for a much more compact camera, with one of the most cost-saving options being a board level camera. This comprises a camera sensor and interface without the housing.

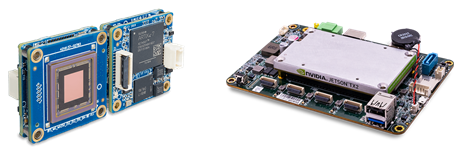

A good pairing for an embedded vision system could be the Teledyne FLIR Board Level BlackFly S combined with the NVIDIA Jetson TX2.

Choosing a Processor for Embedded Vision

The above components are great examples of compact, reliable embedded vision components. NVIDIA’s Jetson family are a range of small form-factor, high-performance computer board that can utilise AI to reinforce processing capabilities at the edge.

Other products similar to the Jetson include the Google Coral and Raspberry Pi. These micro-computers utilise ARM processors to process images and video on the edge – and they represent great options when it comes to embedded vision boards.

If you’re building a larger embedded vision system or machine, there are still compact options available with more power. Taking a larger form but still smaller than most industrial embedded computers, Matrox and Neousys offer systems with processor options from Intel and ARM, with or without powerful NVIDIA GPUs.

Neousys POC-40 is an extremely compact (52 x 89 x 112 mm) fanless computer. It features Elkhart Lake Atom® processor and is designed for space-restricted applications – perfect for embedded vision. Complete with I/O functions, such as two Gigabit Ethernet ports, four USB 3.1 Gen1/ 2.0 ports, four COM ports and optional isolated digital I/Os for industrial communication and control.

The new NRU-120S series from Neousys is a new rugged edge AI-based video analytics PC powered by NVIDIA Jetson AGX Xavier. Larger than the POC-40 but packing a bigger punch, it comprises an 8-core ARM CPU and NVIDIA® Volta GPU with 512 CUDA cores and 64 Tensor cores that offer 11 TFLOPS FP16 or 22 TOPS INT8 computing power.

Smart Cameras for Embedded Vision

Smart cameras are ready-to-go embedded vision devices. They have a camera, processor, I/O, operating system all within a rugged industrial housing, with the ability to run a complete vision application on the device. Some good performers in this category are the new Matrox Iris GTX, new NET iam, and Teledyne FLIR FireFly DL.

With these cameras, you can deploy your own neural network on the camera directly, which eliminates the need for a host PC for classification tasks.

Check out our demo of the Matrox Iris smart camera communicating with a robot arm for pick-and-place applications

Choosing an Interface for Embedded Vision

The most common interfaces for machine vision tend to be GigE Vision, USB3 Vision, CoaXPress and Camera Link.

All four of these interfaces are supported by the EMVA GenICam standard, and all have their own unique advantages.

With embedded vision, we start to see MIPI CSI-2 as a more common interface than typically in other areas of machine vision.

MIPI CSI-2 appeals to volume OEM manufacturers as it is high-performance, low power and low cost. However, there is no standardisation with the software for MIPI CSI-2, so in order to make everything work there is a software development consideration.

If you want to replace or update an integrated MIPI CSI-2 camera to another then you have to complete all of that software work again. This can be a huge consideration if you have a high number or wide variety of devices. With GenICam-compliant cameras you don’t have to worry about the software development to get the cameras working thanks to standardisation.

Embedded Vision Solutions from ClearView Imaging

That’s it for this week’s blog post. We’ve covered the main components needed for an embedded vision system, whether you’re building your own or looking at buying an existing device.

Stay tuned next week to learn more about embedded vision as we dive deeper into camera choice.

Here at ClearView, we have a broad range of knowledge and machine vision expertise to help you decide on the right solution for your project.

We offer a huge range of components, and our experts are happy to help no matter what your question or problem may be. Feel free to get in touch with us and one of our machine vision experts will be ready to help you get going with your project!